5 TIPS ABOUT OUR TP VALVES YOU MUST KNOW!

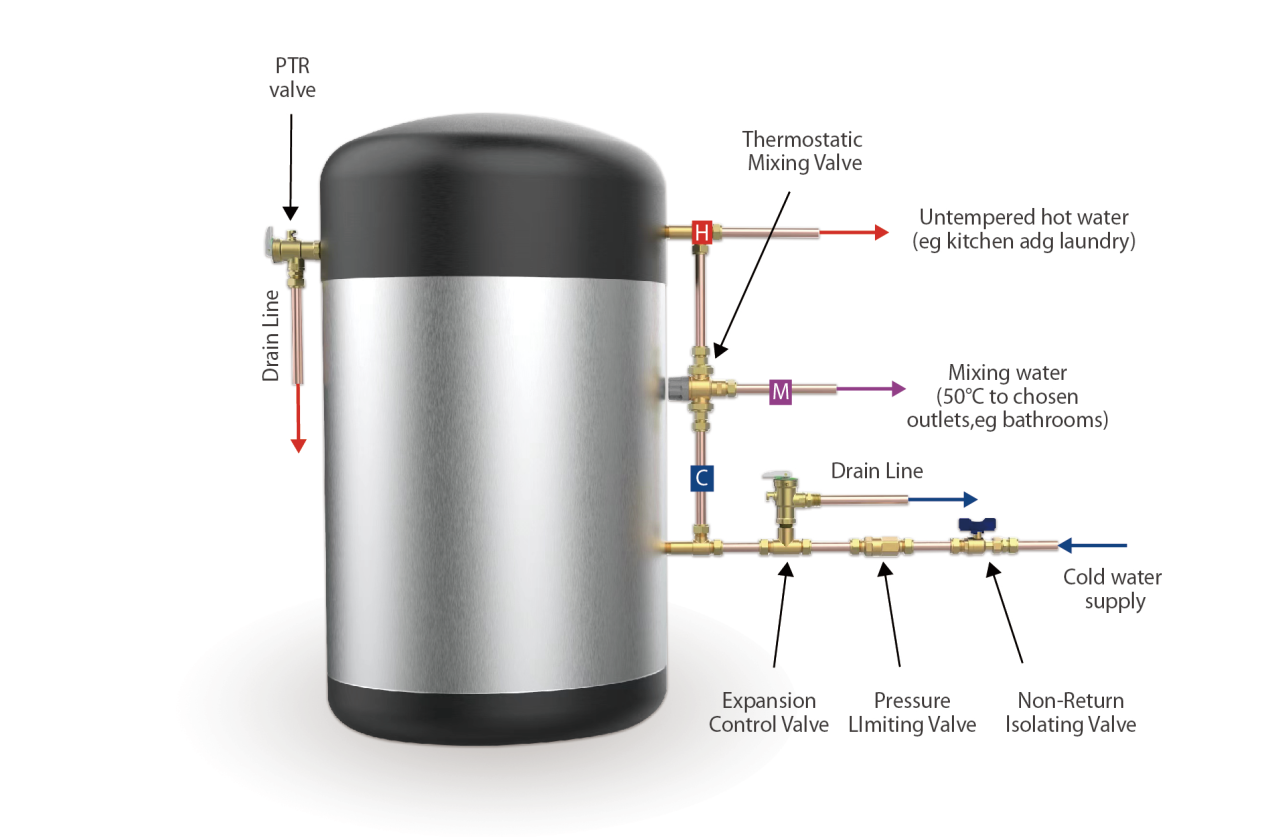

TP valve, we generally known as a Temperature and Pressure Relief valve, is designed to relieve the pressure increase caused by water expansion during the process of normal heating, it serves as a double automatic safety protection device, mainly installed in boilers, water heaters (air water heaters mostly) or pressurized heating water tank.

Principle:

When the heating device is heated to the rated temperature set by the valve, the temperature-sensing element will automatically open the sealing mechanism and discharge the hot water into the drain; due to the formation of water vapor during the heating process, the internal pressure of the sealed heating device will become higher and higher, and when the steam pressure reaches the rated pressure, the valve will also automatically pop up the sealing mechanism to achieve pressure release.

In addition, when the pressure or temperature drops to a certain value, the valve will quickly achieve an automatic reset to close, avoiding the waste of hot water resources.

Application System:

The common TP valve has two kinds of American standard and Australian standard, so what is the difference between these those? Mainly from the opening temperature and structure to distinguish.

Specifications

Material: Brass

Opening Temperature: 90℃~99℃

Reseting Temperature: ≥70℃

Pressure Rating: 500Kpa, 600Kpa, 700Kpa, 800Kpa(850Kpa), 1000Kpa, 1200Kpa, 1400Kpa

Reseting Pressure: ≥85%

DN size: DN15(1/2’’) DN20(3/4’’)

Standards compliant: ANSI Z21.22&EN1490

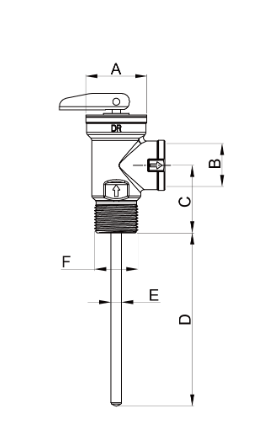

Dimension Drawing

Model | Specification | Dimension | Temperature steam rating | |||||

A(mm) | B | C(mm) | D(mm) | E(mm) | F | |||

930008NT | 1/2’’ | φ37 | Rp1/2’’ | 51 | 94 | φ7 | R1/2’’ | 15,000 BTU/hr |

1/2’’NPT | 1/2’’NPT | |||||||

930003NT | 3/4’’ | φ37 | Rp3/4’’ | 41 | 105 | φ7 | R3/4’’ | 105,000 BTU/hr |

3/4’’NPT | 3/4’’NPT | |||||||

Specifications

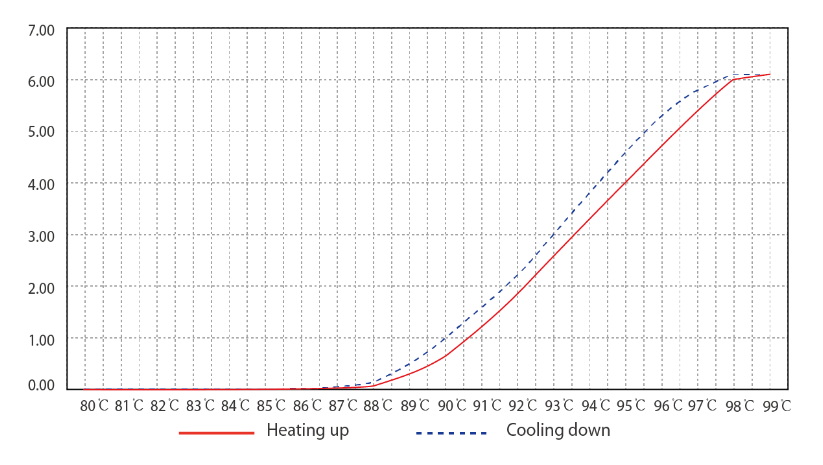

Opening Temperature: 93℃~99℃

Reseting Temperature: ≥70℃

Pressure Rating: 500Kpa、600Kpa、700Kpa 、850Kpa、1000Kpa、 1200Kpa、1400Kpa

Reseting Pressure: ≥90% of the opening pressure

Water-touching metal materials: DZR Brass

DN size: 15mm(1/2") 20mm(3/4")

Expansion rating: 15mm(10KW),20mm(46KW)

Standards compliant: AS1357.1

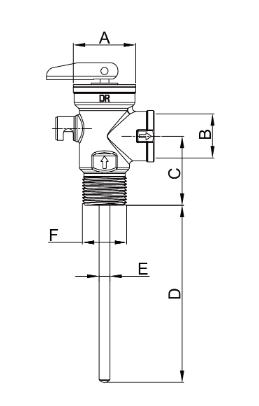

Working Curve & Dimension

Model Number | Size | DIMENSIONS | Expansion Rating | |||||

A(mm) | B | C(mm) | D(mm) | E(mm) | F | |||

930007NT | 1/2’’ | φ37 | Rp1/2’’ | 51 | 94 | φ7 | R1/2’’ | 10KW |

930004NT | 3/4’’ | φ37 | Rp3/4’’ | 41 | 105 | φ7 | R3/4’’ | 46KW |

From the appearance, Australian Standard has an extra overflow port with triple protection than the American Standard.

So what is the difference between SMLG's TP valve and other valves of the same type in the market?

Mainly from the following aspects to elaborate:

1. Metal material for water contact is all DZR dezincification-resistant brass, with better corrosion resistance and longer service life. (Now according to market demand, change to ordinary brass)

2. The internal structure of the product is completely in line with the standard requirements, after the release of pressure, rapid drainage, and drainage of scale; strong capacity for scale, will not affect the sealing of the product due to the deposition of scale.

3. The product adopts the "dry" structure, that is, the spring and other components are separated by rubber ring seals, so that the hot water does not touch the spring when relieving pressure, avoiding the pressure change on the surface of the spring due to scaling, which may cause the valve body pressure relief function to fail.

4. The guide reset mechanism is compact and reliable to ensure that the valve body can quickly and accurately return to the original position even after the valve body is opened at a high flow rate, and no leakage will occur.

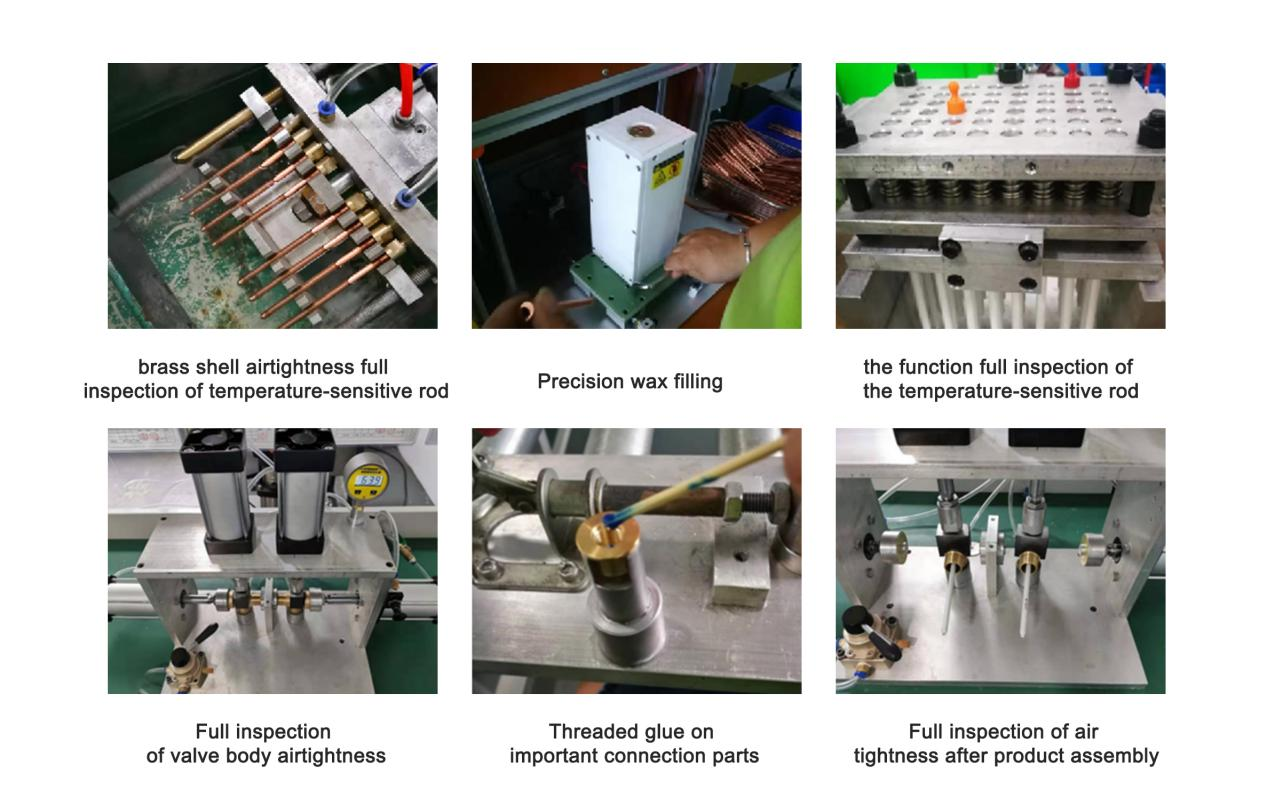

5. We have a strict production process, with quality control from paraffin warm pack filling, calibration, testing, to valve body assembly and testing, thus better guaranteeing the performance of our TP valve.