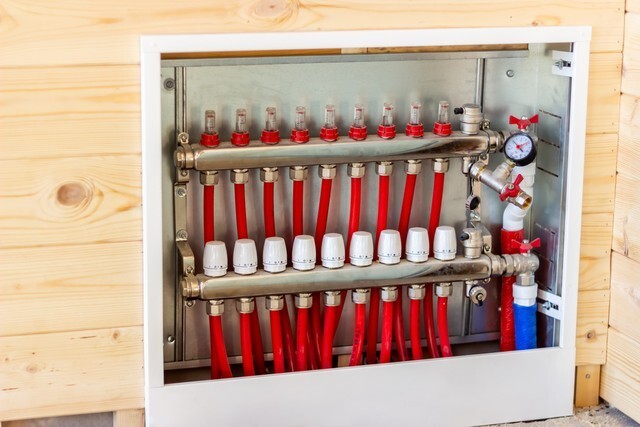

Understanding Stainless Steel Manifolds in HVAC Systems

2024-05-07.

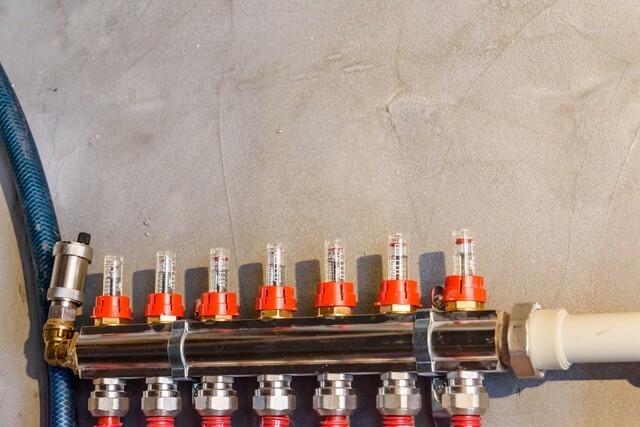

Stainless steel manifolds play a vital role in heating, ventilation, and air conditioning (HVAC) systems, especially in distributing hot water efficiently. These manifolds aim to ensure that the heat of the water is evenly distributed to the different pipes in the system to meet the set temperature requirements.

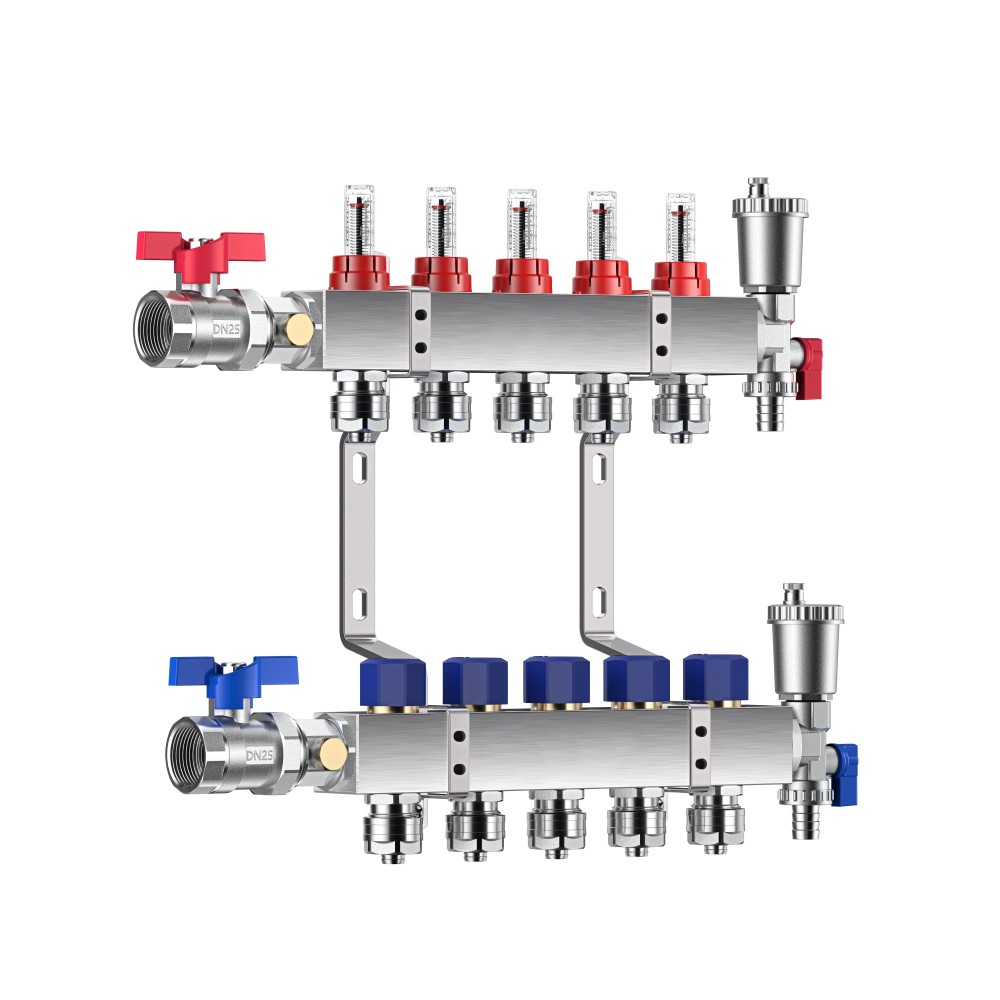

1. Introduction to Manifolds

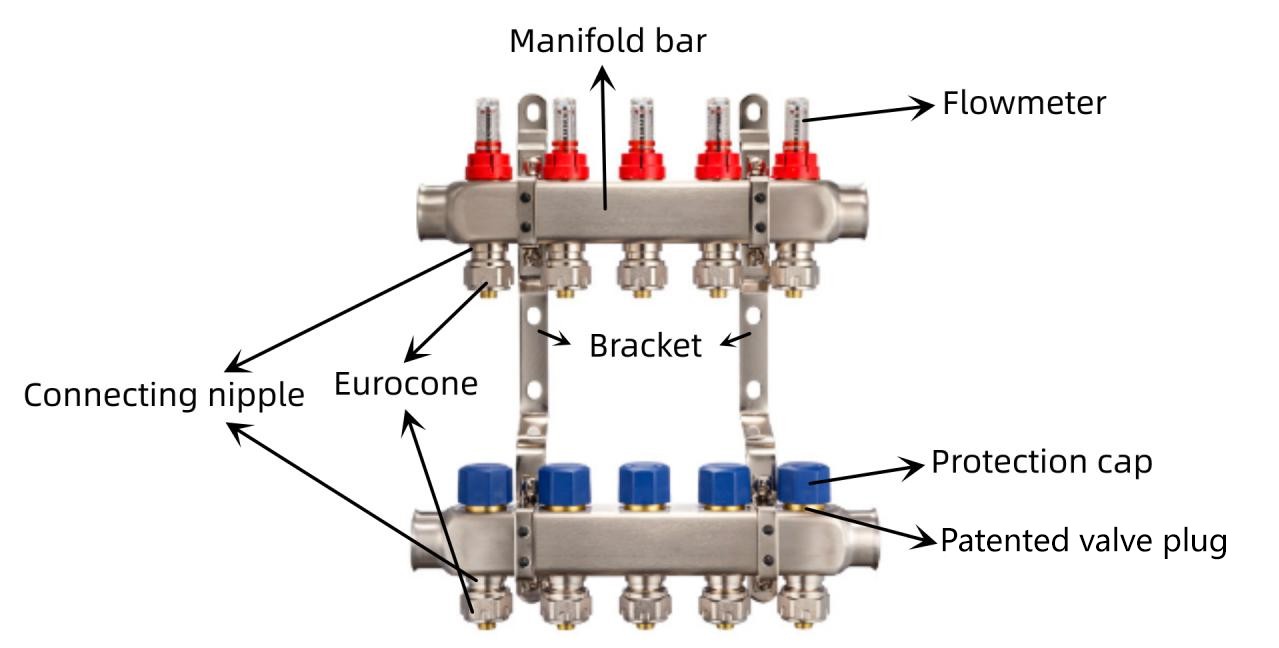

Manifolds consist of several key components, each with a specific function to facilitate smooth system operation. Let's explore some of these components and their functions:

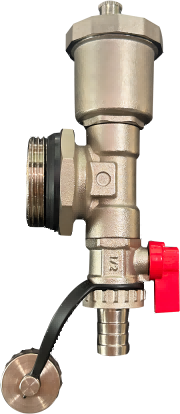

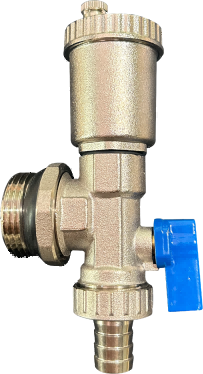

• Ball Valves

It is a head control valve that controls the inlet and return water. In a general installation, the red valve is for incoming water, the blue valve is for return water, and a pressure or temperature gauge is attached to the yellow side.

• Brackets

Brackets are available for mounting the two main bars to a wall or rear panel.

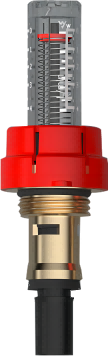

• Flowmeter

The flow meter could help us see if the flow in each pipe is in a balanced condition.

• Manifold Bar

The manifold allows for the installation of various fittings and regulates the level of water flow through the actuator for temperature regulation. It is available in different materials: stainless steel and stainless steel. And various sizes: DN25, DN32.

• Protective Cap

Protective caps shield the manifold from damage during transportation and installation, preventing unnecessary issues caused by exposed valve cores.

• Connect Nipples

• Vent Valve

Vent valves are installed at the end of the manifold to release trapped air from the system, ensuring proper functioning.

• Drain Valve

It could drain the water in the system during pressure testing, system maintenance, and pipe cleaning.

• Temperature Gauge

Used to determine the pressure and temperature within the pipeline.

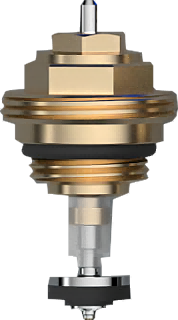

• Valve Plug

The core of the manifold is the valve plug. The patented valve plug, independently developed and designed by SMLG, effectively prevents dirt and sediment from entering the valve plug and extends its service life considerably.

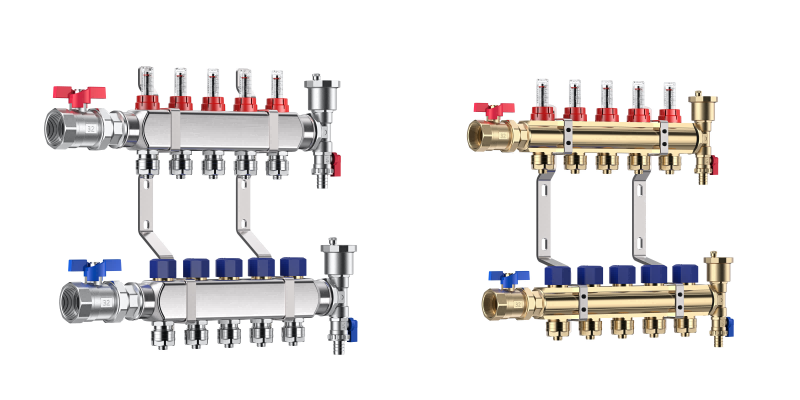

2. Comparing Brass and Stainless Steel Manifolds

The two primary materials currently used for manifolds are brass and stainless steel. Each material offers distinct advantages and considerations. Let's compare the two based on cost, durability, and environmental impact:

• Cost

Compared to stainless steel, which contains many other alloying substances such as chromium and nickel, brass manifolds have a higher copper and lower zinc content, making them more cost-effective. Although stainless steel manifolds are initially more expensive, they offer longer life and durability, making them a cost-effective option in the long run.

• Durability

Both brass and stainless steel have excellent resistance to corrosion and wear in everyday use. However, if it is required for long-term use and needs to withstand high pressure and friction, then stainless steel is better. Stainless steel is composed of iron, chromium, nickel, and other alloying, with high strength and corrosion resistance, suitable for stainless steel kitchenware, medical equipment, chemical equipment, and so on. Brass, on the other hand, is composed of copper and zinc, and although it can also resist corrosion well, it is easy to oxidize over a long period and has a dark yellow surface.

• Environmental Impact

Brass and stainless steel are both recyclable metal materials. However, the wastewater produced by brass during processing will contain heavy metal ions such as copper and zinc, causing environmental pollution. Stainless steel, on the other hand, can reduce the impact of pollution on the environment through particular treatment and is better in terms of environmental protection.

3. Advantages of Stainless Steel Manifolds

Stainless steel manifolds offer numerous benefits that make them an ideal choice for HVAC systems:

• Durability

Stainless steel manifolds can withstand high pressure, temperature, and corrosive environments in HVAC systems, ensuring long-term stable performance and reliability. As a non-reactive material, stainless steel is not susceptible to corrosion caused by chemical reactions, significantly extending the lifespan of stainless steel manifolds.

• Customization

Stainless steel manifolds can be tailor-made for various sizes and configurations to meet specific requirements, effectively adapting to diverse pipelines and heating systems.

• Low Maintenance

Stainless steel manifolds require minimal maintenance and repairs, typically only requiring component replacements when necessary, reducing downtime and operating costs.

• Eco-friendly

Stainless steel is a recyclable material that is reusable in the reproduction process. Since stainless steel does not contain heavy metal elements, it applies to a wide range of everyday applications without fear of affecting water quality. In particular, stainless steel manifolds connected to the water seals have been proven not to cause any negative impact on our daily water use.

In conclusion, the superior durability, customization options, low maintenance, and eco-friendliness of stainless steel manifolds make them a compelling choice for HVAC systems. Investing in stainless steel manifolds ensures long-term performance and cost-efficiency, making them an excellent choice for heating and cooling needs.