What is a manifold?

In the HVAC system, the manifold is a key component and plays an extremely important role. It is not only the hub for delivering hot water to the floor heating system, but also the key to ensure the smooth operation of the entire system. This article will explore all aspects of the manifold, from design features to installation points, and strive to provide a comprehensive perspective and understanding to global users and sellers as a manifold manufacturer.

Material selection

Manifolds are usually made of the following materials:

1. Stainless Steel: Stainless steel manifolds are resistant to high temperatures and corrosion, suitable for long-term operation, and easy to clean and maintain. Stainless steel is a popular and mature product material on the market.

2. Copper Alloy: Copper alloy has good thermal conductivity, which helps to distribute heat quickly and evenly, and also has high corrosion resistance. In addition, although copper alloy is easy to use, some customers may reject products made of this material because heavy metal elements appear in the alloy. Secondly, the price of copper has been unstable this year, and there will be a certain increase in product prices.

3. Plastic: Some economical manifolds may use engineering plastics. Although the cost is low, they may require more frequent maintenance and replacement in long-term use. However, in daily use, or in the floor heating of houses, plastics are unlikely to appear in these occasions, and corrosion or some problems may occur during the water flow process.

Design features

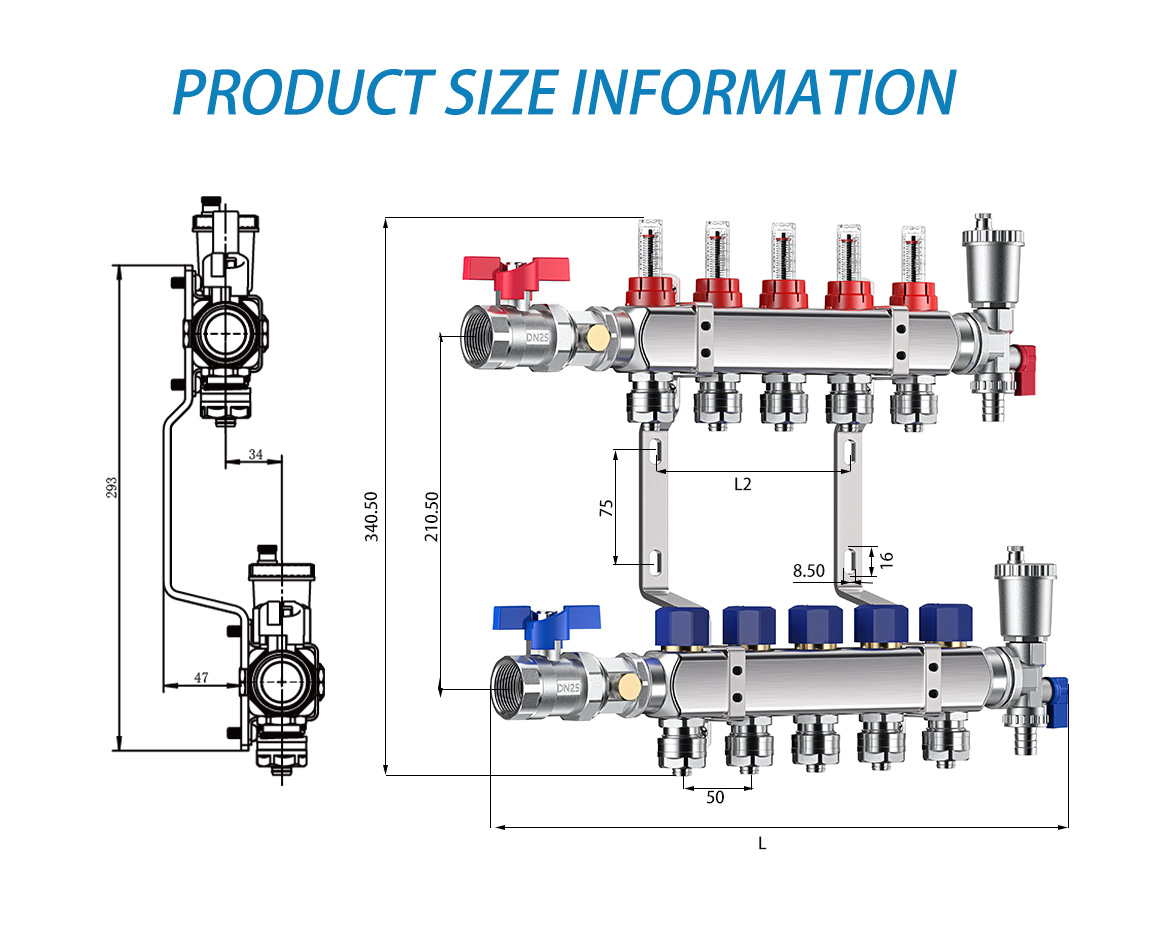

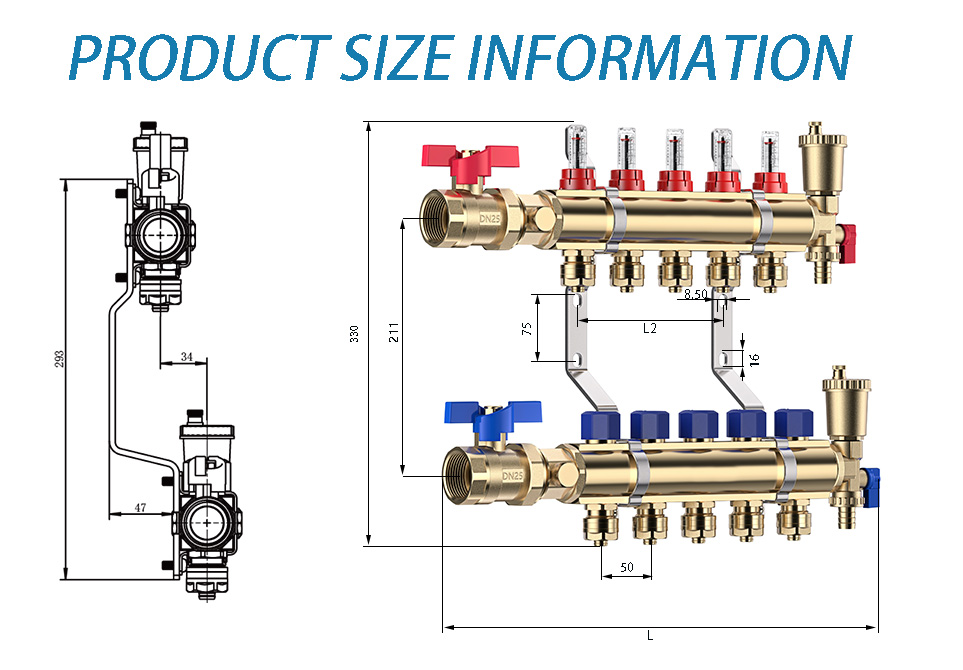

The design goal of the manifold is to achieve efficient hot water distribution and flow control. Typical manifolds usually include the following main features:

1. Multi-way distribution capability: Modern manifolds usually have multiple outlets, which can be connected to multiple floor heating circuits. The water supply of each circuit can be adjusted independently to meet the heat demand of different areas. In order to meet the daily use of the house, a manifold with one port can meet the area of at least 15㎡. For a house of 100㎡, only a manifold with 6 ports is needed. You can calculate how many manifolds you need for your house. Secondly, the multi-way diversion function can realize different temperature settings in different rooms and different regions, thereby saving energy.

2. Flow control valve: Each outlet is usually equipped with an independent flow control valve, which allows precise control of the water flow of each heating circuit, thereby optimizing heat distribution and energy efficiency. As an important control device in the pipeline system, the flow control valve achieves system operation stability, energy efficiency optimization and convenient operation by accurately adjusting the fluid flow. In different applications, the correct selection and reasonable use of flow control valves can significantly improve the efficiency and performance of the system.

3. Temperature control: Some advanced manifolds are equipped with temperature sensors and control devices, which can monitor and adjust the water supply temperature in real time to ensure the comfort and stability of each heating area. The temperature set on the thermostat will be adjusted by the actuator or the temperature-controlled valve above to reach the temperature we want.

4. Material durability: High-quality manifolds usually use high-temperature and corrosion-resistant materials (such as stainless steel or copper alloy) to ensure long-term stableoperation and reduce maintenance requirements. The above two materials are very stable materials, and generally no corrosion problems will occur, which reduces the number of various maintenance times.

Installation points

The correct installation of the manifold is crucial to the performance of the entire floor heating system. The following are the key points to note when installing:

1. Location selection: Choose a location that is convenient for pipe connection and maintenance to install the manifold. It is usually recommended to install it in the center of the floor heating system or where the pipe enters the floor. Both locations have their pros and cons. If it is installed in the center of the floor heating, the distance from the pipe to the room may be too far, affecting the temperature of the water in the pipe and the length of the pipe will be greatly increased. If it is installed at the place where it enters the floor, you need to think of some ways to hide the manifold equipment in the cabinet to achieve the aesthetics of the room.

2. Pipe connection: Make sure that the water inlet and outlet pipes of the manifold are correctly connected to the floor heating circuit pipe and are well sealed to prevent water leakage and energy loss.

3. Electrical connection: If the manifold is equipped with an electric flow control valve or temperature control device, ensure that the electrical connection meets safety standards and is compatible with the main control system.

4. Testing and debugging: After the installation is completed, perform water pressure testing and functional debugging of the system to ensure the stable operation and good effect of the manifold and the entire floor heating system.

Summary

As the core component of the floor heating system, the design and installation quality of the manifold directly affect the performance and efficiency of the entire system. When selecting and using manifolds, floor heating builders and suppliers should pay attention to their design features, installation points, and compatibility with the overall system. Through reasonable selection and correct installation, the comfort, energy efficiency, and durability of the floor heating system can be maximized, thus providing users with a floor heating experience.